Total alkalinity 600 ppm maximum.

Boiler water hardness limit.

Total silica 150 ppm maximum.

In treated waters alkalinity may also be contributed by hydroxide phosphate silicate and.

Scale is a buildup of solid material formed on internal boiler surfaces when the concentration of impurities in the boiler water exceeds their solubility limit and precipitation occurs.

Phosphates are used to react with calcium hardness in the boiler water.

The purity requirements for any feed water depend on how much feed water is used as well as what the particular boiler design pressure heat transfer rate.

Alkalinity test in natural waters alkalinity is most commonly the result of bicarbonate and carbonate ions.

This value will limit the silica content of the steam to 0 25 ppm as a function of selective.

A serious loss of boiler efficiency and possibly boiler failure.

It is desirable to keep the concentration of phosphates in the water to 30 50 ppm in order for complete reaction of the phosphates with the calcium hardness entering the.

Iron oxide is of particular concern in today s boiler water treatment programs.

This can be written as.

Maximum flow velocities in water systems water velocities in pipes and tubes should not exceed certain limits.

Water treatment recommendations vary depending on the operating pressure of the boiler the application steam or hot water and other parameters.

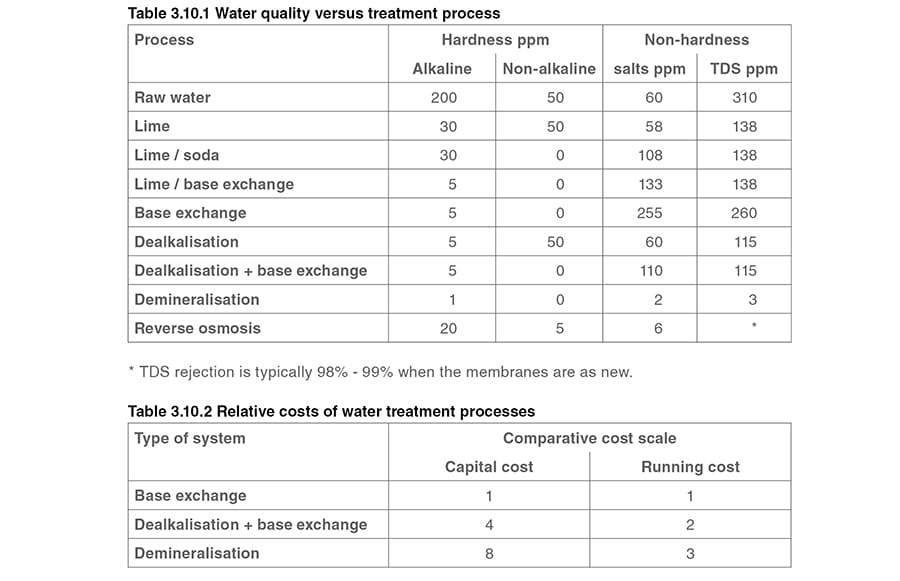

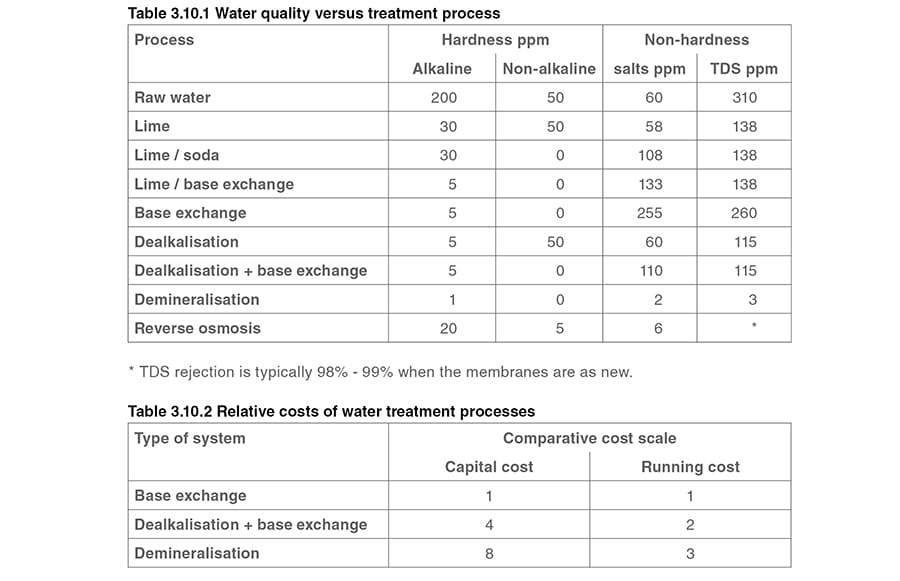

Some impurities such as hardness iron and silica are of more concern for example than sodium salts.

Presented by cleaver brooks steve connor.

Crystals form crystals from scale.

General guidelines to prevent corrosion and scaling in low pressure boilers are as follows.

For boiler water the conductivity increases at the rate of approximately 2 of the value at 25 c for every 1 c increase in temperature.

Asme limits conductivity 7000 umhos neutralized.

Total hardness 1 ppm maximum.

Feed water purity is a matter both of quantity of impurities and nature of impurities.

An increase in temperature results in an increase in electrical conductivity.

A boiler that makes up 4000 gal day of water having 100 ppm of hardness has a potential of accumulating over 1000 pounds of scale per year.

Small amounts of hardness and iron can get into the boiler.

In order for this reaction to take place it is important to maintain a ph at a minimum value of 9 50.

Feed water treatment to avoid corrosion make up water to steam boilers should be treated with oxygen scavengers to avoid serious corrosion problems.

73 control feed of chemicals that prevent scale.

Steam boiler rating and feed water temperature boiler output and feed water.

Feed water boiler water characteristics as per is 10392 1982 1 feed water parameters upto 20 kg cm2 21 kg cm2 to 39 kg cm2 40 kg cm2 to 59 kg cm2 unit total hardness 10 1 0 0 5 ppm as caco 3 ph value 8 5 9 5 8 5 9 5 8 5 9 5 dissolved oxygen.

Conductivity control in the boiler.